Ever wonder what it takes to build a custom bike frame? We are taking a little dive into the minds of some of our favourite local Canadian custom frame makers to get a glimpse of where they came from, why they do what they do, and whats next for them. And perhaps give you inspiration for your next dream build.

First up we have a chat with Alex from Archibald Cycles, who have just released their AC1 custom full suspension mountain bike.

Who are you, where are you from, what’s your favorite color?

I am Alex Troughton, born in Vancouver but with family from Cape Breton Nova Scotia (Where the Archibald family line stems from). A rich forest green is easily my favourite colour.

How, why, and when did you get into building custom bikes?

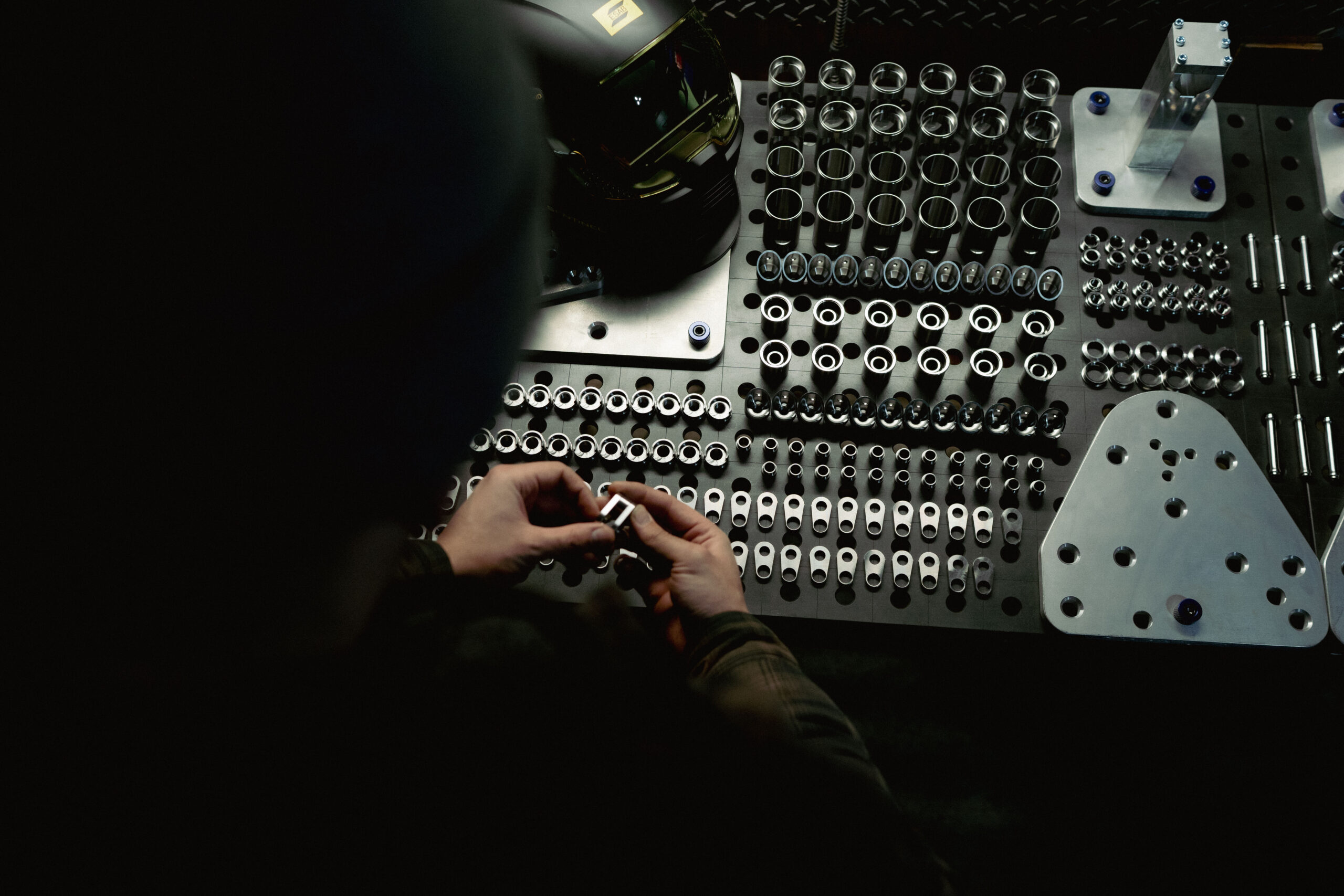

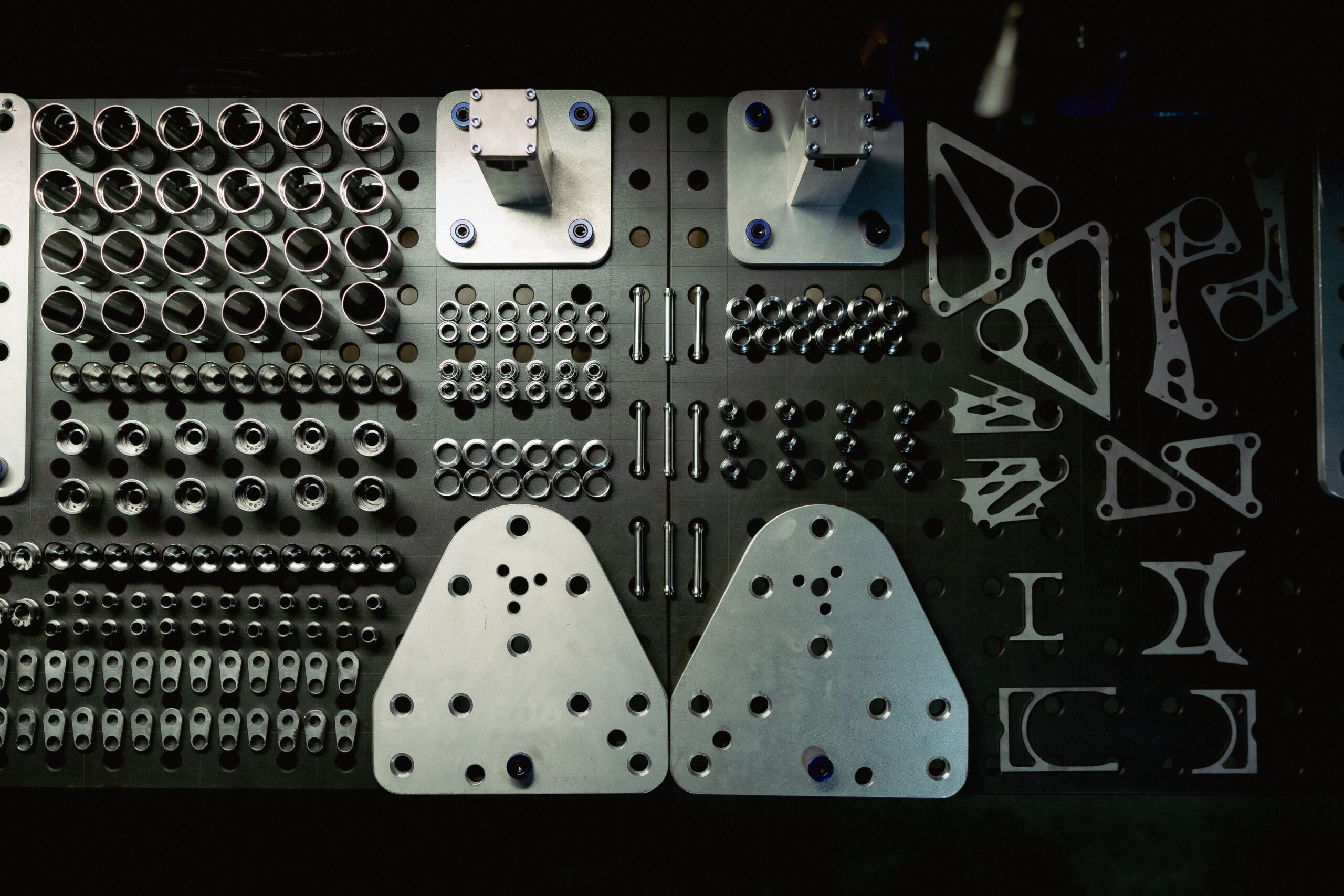

I started wrenching on bikes as a kid out of necessity; building and riding sketchy dirt jumps quickly shows the weak points of a cheap bike. I then took a job at Blackspire Designs in High School where I learned to run and program CNC machines and later designed pedals, chainrings and bash guards. Eventually I started working on a design for my own bike in University around 2019 that grew into the very first AC1 which is still being ridden today. I have always wanted a bike that ticked all of the boxes, and building it myself seemed like the best way to get that.

What has been the biggest challenge to get to where you are now in the industry?

The biggest challenge has been developing the operational side of the business. Luckily with the help of some great advisors the business is now standing on a strong foundation that will allow for smoother growth than I could have done on my own.

How do you work with clients to determine their needs/wants when designing their bikes?

I always want to get to know my clients and what they like to ride. So much of frame sizing is about feel and not always just about body size, so it’s important to really understand what kind of trails they ride and how they attack them. Typically we will discuss the bikes they have ridden previously to get an idea for what they like and dislike, then for local riders clients I will invite them by the shop for a test ride on a prototype to see where they need adjustments.

What are your favorite materials, techniques, and parts to use when building bikes?

Stainless steel is proving to be a fantastic choice after building the original bikes from chromoly. The increased strength of the KVA MS3 stainless steel is really impressive and allows for very clean fabrication. WeAreOne has also been fantastic for supplying the wheels and cockpits for the AC1, they were the obvious choice and have really stood up to everything we can throw at them.

What is your favorite bike you have built to date?

The next bike is always my favourite, but my personal bike which was the third bike built has been an awesome ride for a couple years now. I’ll be replacing it with a new one soon now that I have made some design updates.

Where do you see yourself and your brand in the future? 5 years on? 10 years?

The goal is to move into a larger shop space where we can have a demo showroom with a service center, offices and manufacturing all under one roof. In 5 years I’d like to see an AC1 everytime I go out for a ride on the North Shore. In 10 years I’d like to be hosting races and funding trail building to keep the sport growing

Any shoutouts?

A huge thank you to all of my family that have helped me get this far. The first few years of development would have been brutal without them.